Unlocking Packaging Potential: The Benefits of Cold Sealable Base Paper Spots

Release time

2024-10-28

1. Introduction to Cold Sealable Base Paper Spots

In the world of packaging, innovation is key to staying competitive and meeting consumer demands. One of the most exciting advancements in this field is the development of **cold sealable base paper spots**. These specialized papers allow manufacturers to create packaging solutions that are not only efficient but also environmentally friendly. It’s essential to understand the unique properties of cold seal technology and how it can unlock the potential of your packaging products.

2. The Science Behind Cold Seal Technology

Cold seal technology involves a unique adhesive that bonds at room temperature, eliminating the need for heat during the sealing process. This method is particularly advantageous for sensitive products that may be damaged by high temperatures. The cold seal adhesive is often applied in specific spots or patterns on the substrate, allowing for customized sealing configurations.

This technology utilizes specially formulated adhesives that are activated by pressure rather than heat. When the two surfaces come into contact, the adhesive forms a bond, creating a secure seal. This process not only improves packaging integrity but also reduces energy consumption, making it a sustainable choice for modern packaging needs.

3. Advantages of Using Cold Sealable Base Paper

3.1 Enhanced Packaging Integrity

One of the primary benefits of cold sealable base paper spots is their ability to create strong seals without the need for heat. This feature ensures that products remain intact and undamaged, particularly in sensitive applications such as food and pharmaceuticals. The strength of the seal enhances the overall integrity of the packaging, minimizing the risk of contamination and spoilage.

3.2 Improved Efficiency in Production

Cold sealing technology streamlines the packaging process, reducing production time and costs. With no need for heating equipment, manufacturers can save on energy expenses and increase throughput. Additionally, the cold seal process allows for faster changeovers between different packaging designs, enhancing flexibility and responsiveness to market trends.

3.3 Versatility Across Various Industries

Cold sealable base paper spots are not limited to one specific industry. Their versatility makes them suitable for a wide range of applications, from food to pharmaceuticals to consumer goods. This adaptability allows businesses to experiment with different packaging designs and materials, catering to diverse consumer preferences.

4. Applications of Cold Sealable Base Paper

4.1 Food Packaging Solutions

The food industry is one of the primary beneficiaries of cold seal technology. **Cold sealable base paper** is used extensively in packaging snacks, confectionery, and frozen foods. The ability to seal at room temperature helps preserve freshness and extends shelf life, crucial factors for food manufacturers looking to maintain product quality.

4.2 Pharmaceutical Packaging

In the pharmaceutical sector, packaging integrity is paramount. Cold sealable base paper is ideal for blister packs and other forms of medication packaging, providing a secure barrier against moisture and contaminants. This technology not only protects the products but also ensures compliance with stringent health and safety regulations.

4.3 Consumer Goods and Retail Packaging

Beyond food and pharmaceuticals, cold sealable base paper finds applications in consumer goods packaging. From cosmetics to household products, brands are leveraging cold seal technology to enhance their packaging appeal and functionality. The ability to create visually appealing and secure packages helps brands differentiate themselves in a crowded market.

5. Sustainability in Cold Sealable Technology

As sustainability becomes increasingly important in packaging, cold sealable base paper offers several eco-friendly advantages. The elimination of heat in the sealing process reduces energy consumption, contributing to a smaller carbon footprint. Additionally, many cold seal adhesives are formulated with biodegradable materials, aligning with the growing demand for sustainable packaging solutions.

By choosing cold sealable base paper, companies can not only meet regulatory requirements but also appeal to environmentally-conscious consumers who prioritize sustainability in their purchasing decisions.

6. Innovation and Future Trends in Packaging

The packaging industry is constantly evolving, and cold seal technology is at the forefront of innovation. As manufacturers continue to seek effective solutions that cater to consumer needs, we can expect to see advancements in cold seal formulations and applications. Emerging trends, such as smart packaging and interactive designs, are likely to incorporate cold seal technology, enhancing user engagement and product information accessibility.

Additionally, the rise of online shopping has increased the demand for packaging that can withstand the rigors of shipping while maintaining product integrity. Cold sealable base paper spots are well-positioned to meet these evolving needs, offering robust protection without compromising on sustainability.

7. Frequently Asked Questions (FAQs)

What is cold sealable base paper?

Cold sealable base paper is a specialized paper product coated with an adhesive that bonds at room temperature, enabling secure packaging without heat application.

What are the benefits of using cold seal technology?

The benefits include enhanced packaging integrity, improved production efficiency, versatility across various industries, and reduced energy consumption.

Which industries primarily use cold sealable base paper?

Cold sealable base paper is widely used in the food, pharmaceutical, and consumer goods industries.

Is cold seal technology environmentally friendly?

Yes, cold seal technology reduces energy consumption and can utilize biodegradable materials, making it a sustainable packaging option.

How does cold seal technology improve production efficiency?

It streamlines the packaging process by eliminating the need for heating equipment, allowing for faster production and easier changeovers between packaging designs.

8. Conclusion: Embracing Cold Seal Technology for Packaging Success

In conclusion, cold sealable base paper spots represent a significant advancement in packaging technology, offering numerous benefits across various industries. From enhancing packaging integrity and efficiency to promoting sustainability, cold seal technology is poised to become a vital component of modern packaging solutions. By embracing this innovative approach, businesses can unlock new potentials in their packaging strategies, ensuring they remain competitive in an ever-evolving marketplace.

RELATED NEWS

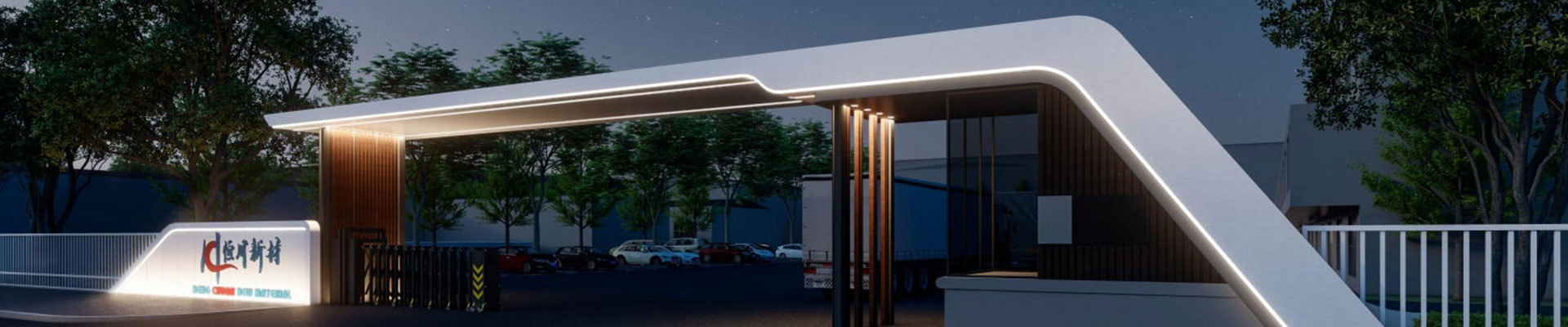

Hengchuan phase II is basically put into use

Hengchuan New Materials Phase II project is basically put into use with a total investment of more than 54.8 million dollars, including two new packaging paper production lines, with an annual capacity of 50,000 tons.

The Versatile World of Food Packing Paper

In the realm of food packaging, wholesale food packing paper plays a crucial and versatile role.

Hengchuan New Material Company Won Second Prize of National Science and Technology Progress Award

On November 22, Zhejiang Science and Technology Awards Conference was held in Hangzhou.

The Wonders of Aqueous Coating Paper

Aqueous coating paper is a remarkable material that has gained significant importance in various industries.

The Versatile and Essential Silicone Greaseproof Paper

Silicone greaseproof paper is a remarkable material that has become an integral part of various industries and our daily lives.

The Versatile World of Industrial Wrapping Paper

Industrial Wrapping Paper comes in various forms and grades, each designed to meet specific needs. It can be made from different materials such as paper, plastic, or a combination of both.